Double acting NBR piston seal for one piece pistons, incorporating Polyester anti-extrusion rings & POM bearing rings.

- Design -

Designed for use on one piece pistons, the five part assembly consists of an endless precision rubber moulded sealing element supported at each end with angle split support rings. The support rings are designed to accommodate split Polyacetal anti-extrusion bearing rings.

The design allows the anti extrusion bearing rings to react positively to increasing pressures. The final assembly provides a robust sealing unit designed to operate at higher pressures.

The seal is also suitable for existing two piece pistons of the same housing dimensions.

- Operating Conditions -

Maximum PressureMax Speed

| Temp. Range

| Temp. Range

|

m/s

| -30°C to 80°C

| -30°C to 100°C

|

0,5

| 400 Bar

| 300 Bar

|

0,15

| 500 Bar

| 400 Bar

|

These range perameters are Maximum simultaneous conditions.

Optimum service conditions are affected by temperature, speed, pressure, surface finish and extrusion gaps.

- Housing -

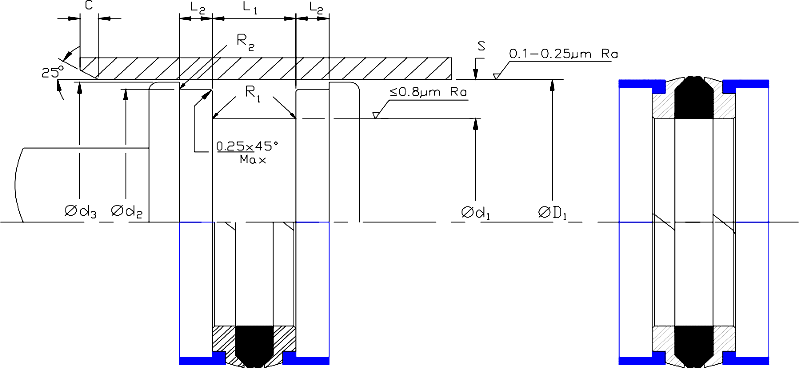

For surface finish and recommended lead in chamfers refer the illustration below. For housing dimensions and machining tolerances refer to the table of recommended sizes and

Tolerance Tables for value of tolerence symbols

- Fitting -

Fit seal onto the piston in the following sequence.

1- Rubber Sealing Element

2- Support Rings

3- Polyacetal bearing rings.

It is important that care be taken in fitting the seal within its housing. For details refer to

Seal Installation.