Single acting NBR energised Bronze filled PTFE piston seal for one piece pistons.

- Design -

The Claron style 851 is a heavy duty single acting seal for hydraulic or pneumatic piston applications.

Designed as a high pressure - low friction seal for use singly, in tandem sealing arrangements or back to back for double acting applications without pressure lock.

- Materials -

Standard materials are Bronze filled P.T.F.E with a Nitrile O-Ring Energiser but both the outer sealing element and the energiser are available in a wide range of high performance materials to suit a variety of applications . The application parameters should be carefully considered prior to selecting suitable materials from the tables.

Consult Claron for further advice.

- Operating Range -

Temp. -54°C to 200°C (Dependent upon O-Ring Material used See

Appendix 2)

Pressure upto 800 bar

Velocity upto 15m/s

These range parameters are maximum conditional values.

Optimum service conditions are affected by temperature, speed pressure, surface finish and extrusion gaps.. Refer to

Seal selection Guide for further information.

- Operating Conditions -

Maximum PressureTemp. Range

| Temp. Range

|

-30°C to 80°C

| 80°C to 120°C

|

400 Bar

| 350 Bar

|

These range perameters are Maximum simultaneous conditions.

Optimum service conditions are affected by temperature, speed, pressure, surface finish and extrusion gaps.

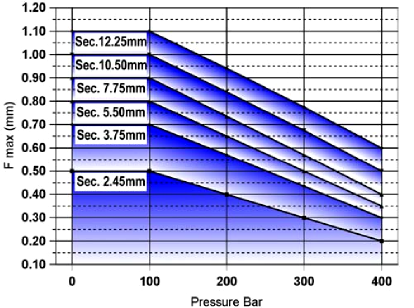

Diametrical Clearance F shown in the graph is calculated as the maximum permissible extrusion gap, allowing for movement due to side load, for various pressures and temperatures upto 80°C. The use of a suitably selected Claron bearing ring will effectively reduce the Radial clearance to a value nearer to F/2 thus increasing the pressure capability of the seal. The maximum seal extrusion gap should be calculated allowing for all tolerances, movement and cylinder expansion.

For pressures > 400 bar, the seal extrusion gap should be reduced by utilising smaller tolerances. e.g H8 for Cylinder bore, f8 for piston diameter.

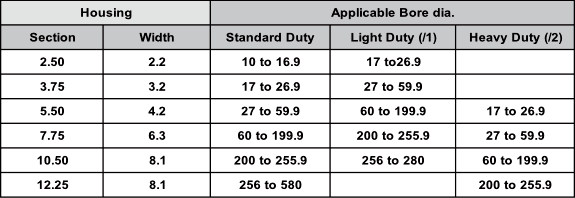

- Range of Installation Dimensions -

The full range of diameters applicable to the "Standard", "Light" and « Heavy » Duty Sections are shown in the table below

- How to Order -

When ordering, prefix the size reference with the style required and use the suffix shown in the

material application tables:

e.g. 851 Standard section in Bronze filled material for 70mm diameter 851-0700/B

851 Light duty section in Glass filled material for 70 mm diameter 851-0700/1G

851 Heavy duty section in Carbon filled material for 70 mm diameter 851-0700/2C

For O-Ring energiser materials other than Nitrile, use suffix shown in material table.

e.g Flourocarbon material (FKM), 851-0700/B/FKM

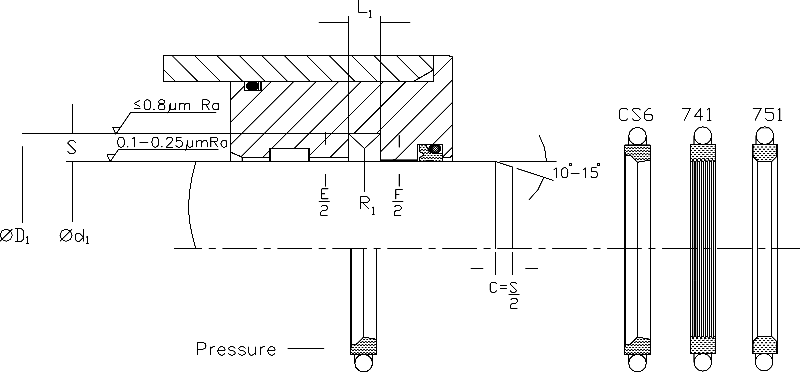

- Housing -

For surface finish and recommended lead in chamfers refer the illustration below. For housing dimensions and machining tolerances refer to the table of recommended sizes and

Tolerance Tables for value of tolerence symbols

- Fitting -

For the seal to function correctly, it is important that care be taken in fitting the seal within its housing. For details refer to

Seal Installation.